Selecting the right cold room panels is necessary for industries in South Africa that require efficient and reliable refrigeration solutions. From food processing to pharmaceuticals, the right panels ensure optimal temperature control, energy efficiency, and durability.

This guide provides key considerations to help South African businesses make informed decisions when choosing cold room panels.

Understanding Cold Room Panels

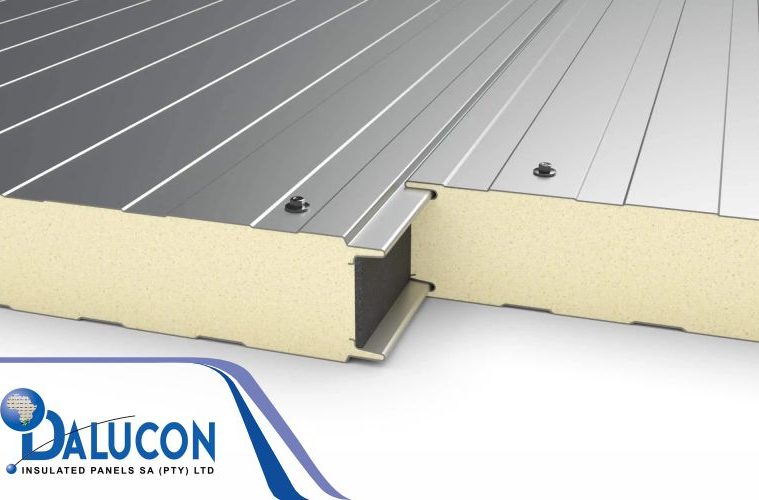

Cold room panels are insulated structures used to build refrigerated spaces. These panels typically consist of an insulating core sandwiched between two outer layers.

The core material can vary, affecting the panel’s insulation properties and overall performance. Common core materials include polyurethane (PUR), polyisocyanurate (PIR), and expanded polystyrene (EPS).

Insulation Performance

The primary function of cold room panels is to maintain a consistent temperature. Insulation performance is measured by the thermal conductivity of the core material.

Polyurethane and polyisocyanurate panels offer superior insulation due to their low thermal conductivity, making them ideal for industries requiring strict temperature control. EPS panels, while less efficient, are a cost-effective option for less demanding applications.

Panel Thickness and Size

Panel thickness directly impacts insulation effectiveness. In South Africa’s diverse climate, thicker panels are recommended for better thermal performance, especially in regions with high ambient temperatures.

Standard panel thicknesses range from 50mm to 200mm, with thicker panels providing better insulation. Panel size should also match the dimensions of the cold room to ensure a precise fit and minimize thermal bridges.

Fire Resistance

Fire safety is a critical consideration in industrial settings. Polyisocyanurate panels are preferred for their enhanced fire resistance compared to polyurethane and EPS.

PIR panels can withstand higher temperatures and slow the spread of flames, providing additional protection for both the facility and its contents. Ensure that the selected panels comply with local fire safety regulations.

Durability and Structural Integrity

Durability is essential for maintaining the integrity of cold room panels over time. Panels should be resistant to moisture, chemicals, and physical impacts. In industrial environments, robust panels reduce maintenance costs and extend the lifespan of the cold room.

Outer layers made from galvanized steel or stainless steel offer excellent protection against corrosion and mechanical damage.

Energy Efficiency

Energy efficiency is a significant factor for reducing operational costs. High-quality insulation minimizes heat transfer, reducing the workload on refrigeration systems. Look for panels with low U-values, indicating better insulation properties. Investing in energy-efficient panels can lead to substantial long-term savings on energy bills.

Environmental Considerations

Sustainability is increasingly important for South African businesses. Choose panels with eco-friendly insulation materials and recyclable components.

Manufacturers offering panels with low global warming potential (GWP) and ozone depletion potential (ODP) contribute to environmental conservation efforts. Additionally, consider panels produced through sustainable manufacturing processes.

Compliance with Regulations

Make sure that the chosen cold room panels comply with South African standards and regulations. Adhering to local building codes and health and safety guidelines is crucial for legal compliance and operational safety. Panels certified by recognized bodies provide assurance of quality and performance.

By prioritizing these factors, businesses can enjoy optimal performance, safety, and cost-efficiency for their refrigeration solutions. Investing in high-quality cold room panels is a strategic decision that pays off in improved operational efficiency and sustainability.

ALSO SEE:

6 must-do fridge maintenance tasks for lower electricity bills

Feature image: Supplied